The difference between a double-sided PCB board and a single-sided PCB board is that the single-sided PCB circuit is only on one side of the PCB board, while the double-sided PCB circuit can be on both sides of the PCB board, with a via in the middle to double-sided PCB board. The lines are connected. Parameters of the double-sided PCB board The manufacturing process of the double-sided PCB board is different from that of the single-sided PCB board. In addition, there is an extra copper sinking process, that is, the process of conducting the double-sided circuit.

1. Single-sided printed circuit boards usually use single-sided copper-clad laminates. Screen etching or photo-imaging is used to make etched circuit patterns on the copper surface. Excess copper foil is removed by chemical etching to form conductor patterns. .

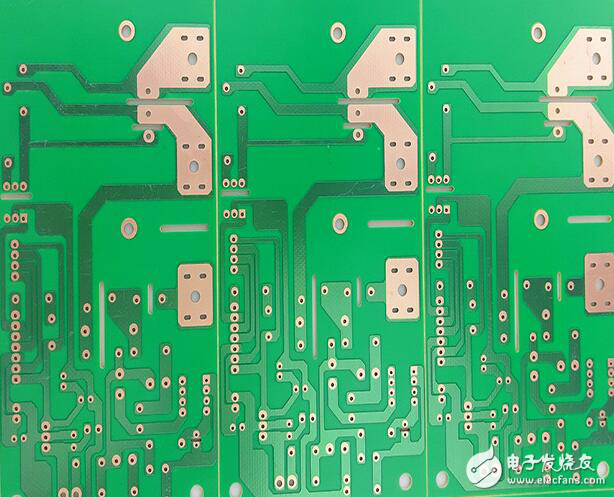

2. The double-sided printed circuit board has upper and lower conductor patterns, and the upper and lower vias are connected by expensive perforations. In the processing of printed circuit boards, the walls of expensive perforations are plated with copper to make the upper and lower layers conductive. Double-sided printed wiring boards usually use double-sided copper-clad laminates, using screen printing or photoimaging. A resist line pattern is made on the copper surface, and the excess copper foil is removed by chemical etching to form a conductor pattern.

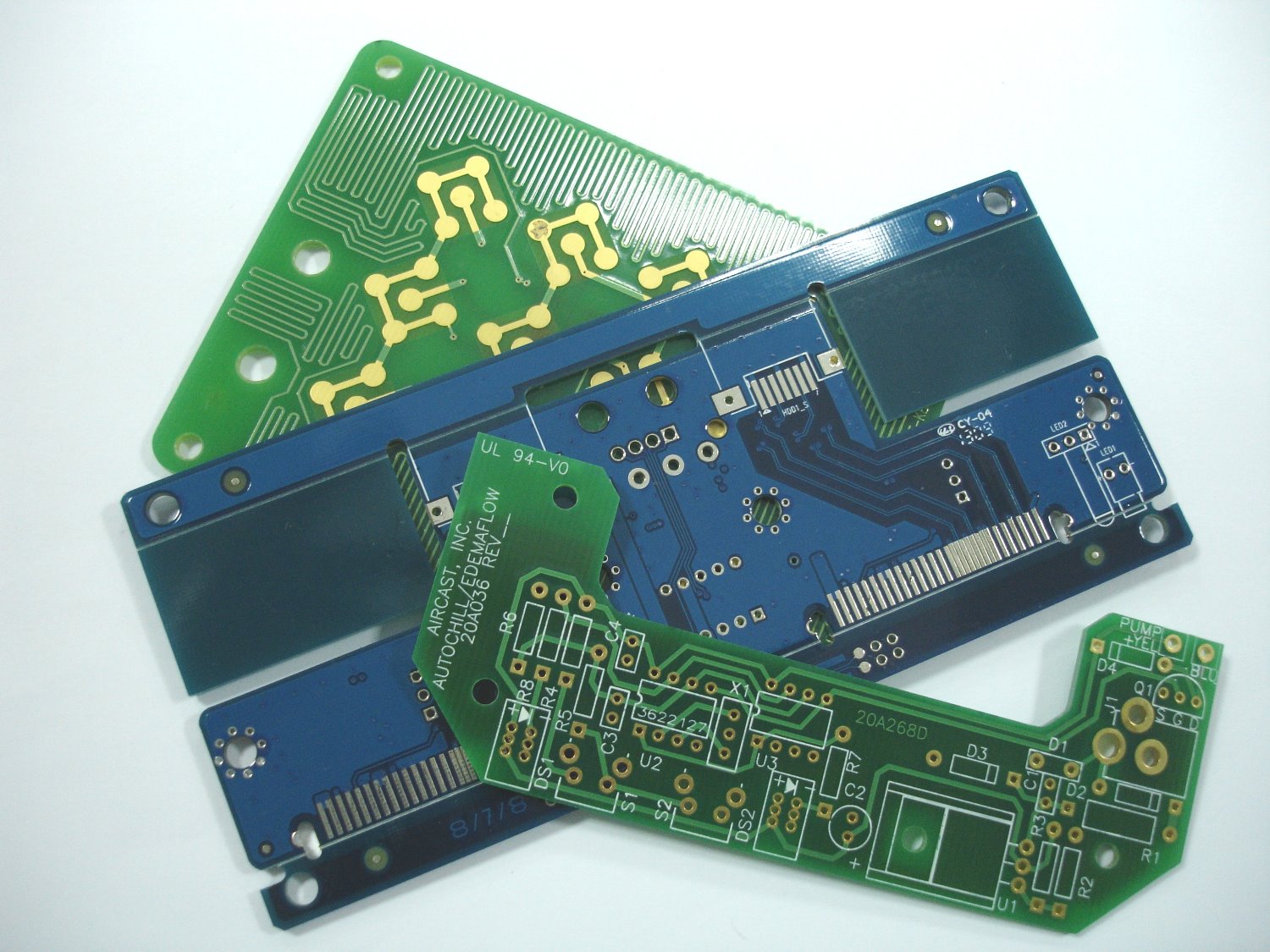

Double-sided PCB boards can be distinguished from single-sided PCBs in appearance. Single-sided boards are circuit boards with only one layer and wire layers. Double-sided boards are circuit boards with two-sided wiring layers. There are vias in the middle, so this is a single The difference between the two panels.