Multilayer PCBA Manufacturer: Introduction to PCBA

We often see that people confuse the multi-layer PCB manufacturer with a multilayer PCBA manufacturer. Although the difference is subtle, still there is a difference. Understanding the difference would help you make the right decision.

After the Printed Circuit Board is an important part of your electronics. It would define, its functionality, efficiency, and effectiveness. Therefore, you should pay close heed to all its aspect. So, to make things easy for you, we are going to talk about PCBA in detail.

We will also highlight its differences and advantages. So, without any further delay let us get started!

A Concise Intro to PCBA

Of course, to understand PCBA, you first need to have the basic knowledge of a Printed Circuit Board. PCB is an important part of modern electronics. It is responsible for connecting the electrical components.

In order to facilitate the functionality of electronics, the board utilizes several copper-etched features including conductive traces and pads. These boards are created by printing a conducting material on the board. The depositing of the material is in the form of a thin layer. It acts as the insulation for the board.

The manufacturer refers to that as the substrate of the board. Later, the components are placed on the board individually. After that the interconnecting of the circuits take place. There are contact fingers attached to the substrate. They are present at the edge and are used for connecting the other PCBs or the external devices.

Define PCBA

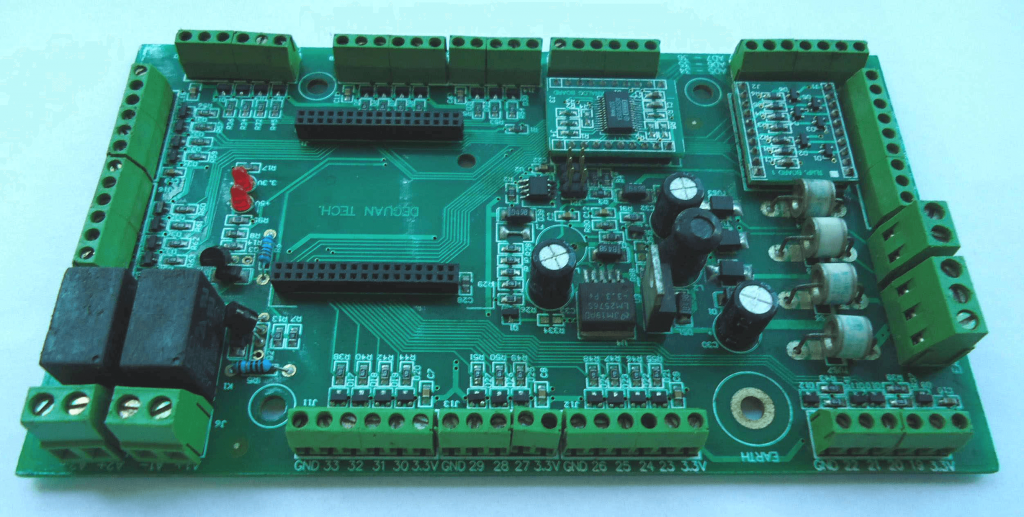

Now that you have an idea of a Printed Circuit Board, we will not talk about the PCBA. It stands for Printed Circuit Board Assembly. Unlike PCB, PCBA means the board that you get after all the mounting operations and printing is completed.

So, when you are confused between PCB and PCBA, remember that Printed Circuit Boar is simply a board with all the required circuity on it. On the contrary, PCBA is the complete package. It contains all the required features and you now can deploy it into your electronics. It does not require any further processing.

There are several components that the manufacturer mounts on the PCBA. Some of these components include modules, triodes, diodes, resistors, inductors, and many more. To establish the connection between the components and the board, the PCBA goes through a reflow furnace heating process.

Remember, the assembly process of the Printed Circuit Board is a complicated and essential part of the manufacturing process. Therefore, it is imperative to take great care during the process. Make sure that only skilled and experienced technicians should handle this process.

In addition, the manufacturer needs to have specialized computer systems. These systems should be up to date and should be of the best quality. They should offer accuracy without compromising efficiency.

By now, you know the difference between a PCB and a PCB. Next, we are going to talk about the assembly methods of a PCBA.

PCBA Assembling Manufacturing

For the assembling of PCBA, the Multilayer PCBA manufacturer uses two main methods. Both these methods serve different purposes and used according to their product requirement. In addition, they are their own pros as well as their cons.

Here are the two primary methods that are used for PCBA component assembling.

Surface Mount Technology

If you are not new to Printed Circuit Boards, you would be familiar with the term “Surface-Mount Technology (SMT). The manufacturer uses SMT when they are working with small size components and circuits.

SMT generates effective results due to its complete automation ability. There is no very little human interface in this technique of component assembling. Therefore, fewer error chances as well as more complicated Printed Circuit Boards.

The fully automated Printed Circuit Board Assembly technique comprises of three main steps.

Step-1: The Printed Circuit Board would need a generous application of solder. It is important that the Printer should supply quality solder to the PCB.

Step-2: Here comes the tricky part. In this step, all the components are placed into their designated locations.

Step-3: To ensure the sealing of the components to the board, it needs to go through a furnace at a 500-degrees. This would liquefy the solder past, thus ensuring that all components will stay put.

Through-Hole Device (THD)

The second technique for PCBA is the thru-hole device. Unlike the SMT, THD does require manual input. It is the combination of both manuals as well as automated operations. There is no denying that it is an effective technique.

However, it is vital that the manufacturer has the best and highly skilled technicians on board. After all, the quality and reliability of the PCBA would greatly depend upon these technicians.

There are three primary steps of the method. We have listed these steps below.

Step-1: The highly skilled technician would have to manually place the components on the Printed Circuit Board. He or she should be extremely cautioned as this will have a great impact on the quality of the PCB.

Step-2: In this step, the rectification and the inspection of the set components are performed. This eliminates any errors made by the technicians.

Step-3: In the last step, the entire Printed Circuit Board Assembling would have to undergo a process we call, Wave Soldering. This is the same step as that of an SMT. IT means that the PCB would pass through a wave of liquid solder at an extremely high temperature. Usually, the temperature is at 500-degrees Fahrenheit.

Printed Circuit Board Assembly Vs Printed Circuit Board

So far, you know the working of PCBA and the definition of PCB. Now it is time to focus on their major differences. These differences tend to step both these terms apart. We did briefly explain the major difference above.

However, we are going to be elaborating on the difference here.

To get straight to the point, PCBA is a fully functional board. On the contrary, PCB is only blank circuity. PCBA comes with all components intact. However, that is not the case with the Printed Circuit Board.

The interesting thing is that to have a PCBA, you would need a complete PCB. After all, the assembling of a certain thing requires that particular thing to exist.

Manufacturing Procedure

Multilayer PCBA manufacturer claim that producing a Printed Circuit Board is way easier in comparison to manufacturing a PCBA. Component attachment is the main reason behind PCBA complexity. In addition, the furnace soldering further adds to the challenge of PCBA manufacturing.

Functionality

Printed Circuit Board is more of a blank board. It does not come with the facility of accommodating electricity. However, this is not the case with Printed Circuit Board Assembling. These boards have everything require.

You can directly incorporate these boards into your final product.

Cost

You will be surprised to know that PCBA is way more expensive in comparison to PCB. The cost of the same board would be very high for a PCBA, whereas it would be extremely low for a Printed Circuit Board.

The reason behind the high cost of PCBA is the additional components. These components are fully responsible for increasing the overall price of the PCBA.

Packaging

Both PCB and PCBA have different packing techniques. For PCBA, manufacturers use either the anti-static packaging or the compartmental packaging. On the other hand, for PCB they rely on vacuum packaging.

Take Away

Printed Circuit Boards are the basics of modern technology. Their quality and efficiency are directly proportional to the quality and efficiency of their respective electronics. Therefore, it is critical to incorporate only the highest quality Printed Circuit Boards.

CCTC-HTPCB is a leading multilayer PCBA manufacturer. They come to have skills and the experience required to generate high quality, complex Printed Circuit Boards. Their PCBA are fully ready for you to implement in your products.

You can reach out to them with your own PCB design, and they will guide you in the best possible way to ensure high quality Printed Circuit Board Assembling.