Facts You Need to Know About Quick Turn PCB Fabrication

Obtaining a quick turn prototype PCB is not sci-fi. Before you start working on your designs, you must acknowledge a few facts about PCB manufacturing.

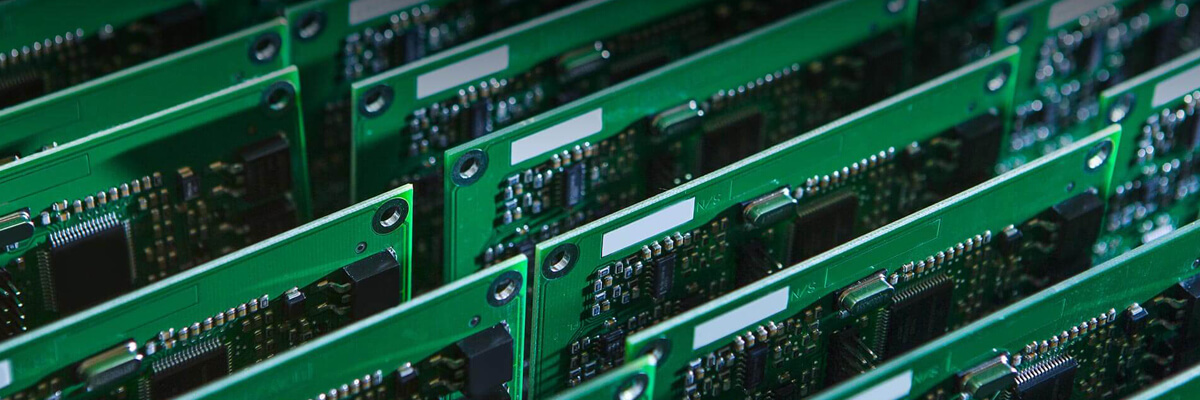

Modern PCBs are the most commonly used electronic devices that are used in high precision. With the ongoing development of the technology, their demand is also increasing day by day.

For this, so many production workshops of advanced PCBs have been opened to help the customers to attain the best time to market and also to get the competitive benefits by producing the PCBs in a viable way at the smallest price through punctuality in delivery, product quality and fabrication capabilities.

- Proven Technology

Multi-layer PCB, professional research, and development on the HDI high density and flex-rigid PCB. Implanting the technology of little size core, wide GEM, and PCB with the exceptional needs from industries such as medical, telecom, automotive, and many more.

- Qualified Materials

One needs to be very selective about the quality of the materials used such as Shengyi, Rogers, DuPont, Wazam, Atotech, Rohm Haas, etc.

What Are the Most Common Mistakes That One Needs to Avoid for the Quick Turn PCB Manufacturing?

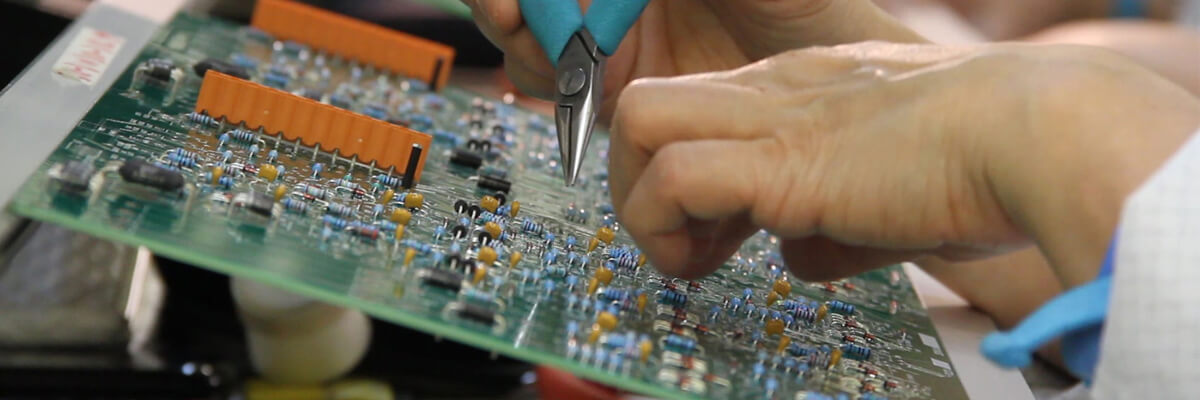

With the standardized technology that is single lamination through holes and an eight layer board, a fairly routine is a routine of one to three days. But there is a thing about PCB prototype quick turn, it can be only as quick as the provided information as well as the current technology with which you are working. You need to be well aware of a few things that can help in slowing down the quick turn.

But what are those things? Don't worry, have a look at them below:

- Laminations

The first thing among all is the various lamination cycles. Let us first begin with the multiple laminations. Each time a person laminates aboard, it feels like building up another multilayered board. This multilayer board goes through all the steps of fabrication. The time taken to complete one lamination cycle is approximately two days. So the process is time consuming to say the least. But this doesn't make the multiple layer laminations less necessary. However, this whole process will essentially contradict the efforts of a quick turn.

- Through in Pad Plated over

The via-in-pad is another example that applies here to single stack up laminations. If your surface mount footprints have via in the pad then it can make the solder absorb into the hole. Sometimes, you need to keep the heat away from this process to save space. Moreover, vias in pads became so common. Be alert that it can also add up one day to the whole cycle.

- Fabrication Drawing

You need to be aware of the notes that you keep on the fabrication drawing. Most importantly, you need to understand exactly what your notes are to the fabricator.

- Soldermask

For instance, let's have a look at the dams and tenting of the solder mask. To cover up the hole and to make an airtight seal, you would require to plug in the via with the solder mask. After that, return and put the coating on the other leftover parts of the board. This is a duplication of the same process.

- Surface Finish

Surface finish is one of the most time-consuming processes. If the board needs two kinds of gold finishes. The hard gold finish for edge connectors and the ENIG gold finish for the surface mounts. When you do this that means you are adding double gold to the process of plating. Moreover, the finishes must be separately plated. Most importantly, as soon as this process gets completed, then go through it again.

Quick Turn PCB Fabrication

The Quick turn PCB fabrication is the most convenient and fast with a turn around of a day. Most of the customers love outsourcing their PCBs from the most professional manufacturers other than performing it in the house. Also, it can save the manufacturing cost and stress.

If this is the case, then manufacturers need to be in tune with demand from the market. It has facilitated speedy PCB fabrication turn around and manufacturing.

Various factors determine the turnaround of the capabilities of the business. Among the most underappreciated and largest manufacturing and printing circuit boards. Besides, quick turn fabrication can make the time to market better in numerous ways. Some of the most important are as follows:

Location: It is one of the most critical factors in the case of quick turn PCBs. So, the farther the partner of PCB fabrication is, the longer it will take to deliver the PCB. For some people, this may not be the most critical issue. But, if a business needs sudden time to market and speedy turnaround time, then the PCBs must arrive fastest as possible.

Time of prototype development: Of course, the prototypes are laboriously featured in the new products of the market. Either PCBs can contribute to the quick turnaround time or they can cause necessary delays all along with the development of the prototype.

As soon as the prototypes get produced, the firm will start production on a large scale. Moreover, quick turn prototypes of PCB are so impactful here.

Quality PCB: The product quality is always quite significant. When a company prepares to launch a new product in the market, then they should first assure that whichever item is in question must meet all the standards and expectations of the people. Also, if there are some shortcomings then they must be addressed as soon as possible.

Consistency: Going to the market doesn't only mean developing a product to store it on the shelves but it means the large-scale production of details. And that's where the consistency of PCB fabrication enters the whole picture.

Conclusion

This was all about the quick turn PCB fabrication. Here we have noted down everything that you need to know. Hope you are satisfied with the article, please let us know in the comment section.

If you want more information, please contact us.