|

Sample PCB Producing Leadtime |

||

| PCB Layer Leadtime | Lead Time (Working days,ex-factory) | |

| Urgent (hour) | Normal (day) | |

| 1 ,2L | 12 | 4--5 |

| 4L | 36 | 5--7 |

| 6 ,8L | 72 | 7--9 |

| 10 L and up | To be determined based on gerber file | |

| The above lead time is based on: | 1.Matrial Available | |

| 2.All Engineering issues comfirmed | ||

| PCB Mass Producing Leadtime | ||

| PCB Layer Leadtime | Lead Time (Working days,ex-factory) | |

| Urgent (day) | Normal (day) | |

| 1 ,2L | 3--7 | 8--10 |

| 4L | 7--9 | 12--14 |

| 6 ,8L | 12--14 | 15--18 |

| 10 L and up | To be determined based on gerber file | |

| The above lead time is based on: | 1.Matrial Available | |

| 2.All Engineering issues comfirmed | ||

| PCB Engineering Capacity | ||

| ITEM | STANDARD | ADVANCED |

| MAX Layer Count | 16 | 24 |

| MAX Board Size | 530 ×610mm | 2000 ×610mm |

| MAX Board Thickness | 6mm | 10mm |

| Min Board Thickness | 0.25mm( 2 layer ) 0.40mm(4 layer ) |

0.20mm(2 layer) 0.38mm(4 layer) |

| Max Surface Cu Thickness | 6OZ | 12OZ |

| Line Width/Spacing | 0.075mm/0.075mm | 0.075mm/0.065mm |

| Min S/M Bridge | 0.10mm | 0.075mm |

| Min PTH Hole Size | 0.20mm | 0.15mm |

| Outline Tolerance | ±0.125mm | ±0.10mm |

| Min PTH PAD Size | 0.45mm | 0.40mm |

| PTH Aspect Ratio | 8:01 | 10:01 |

| Drill Position Accuracy | ±0.05mm | ±0.05mm |

| Impedance Control Single- ended/Differential |

±10% | ±8% |

| Bow and Twist | 0.75% | 0.50% |

| Materials | FR4/Halogen free/ Rogers/Aluminum/Hybird |

|

| Surface Finishing | ENIG/OSP/Gold Plating(Soft/hard) /HASL/Imm. Silver/IMM.Tin/Tin Plating/Carbon Ink/Selective /Imm.metal+OSP |

|

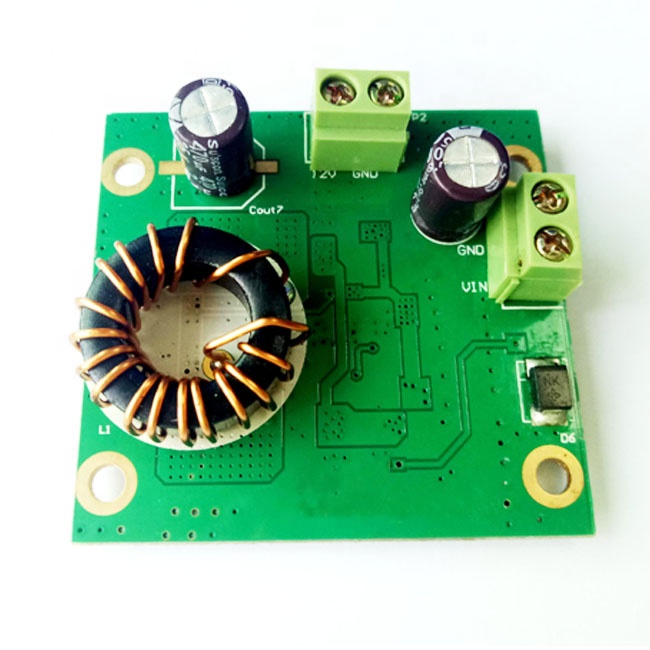

Cost Reduction:

This is the most important benefit of your long term relationship with us. After learning your specific needs, with the Shenzhen strong supply chain support ,we will quickly work out a solution to meet your expenses and cost reduction targets. They may be achieved by providing lower cost PCB, PCB assembly or by our reengineering or designing services to meet your expectations.

DFM Analysis:

Because we are capable of handling DFM analysis, PCB fabrication, PCB assembly, and components sourcing under one roof, which can avoid mistake before manufacturing .

Saving Your Time:

We save your time transition from one phase of a project to another. For instance, from layout-to-fab, fab-to-assembly, parts procurement-to-assembly. We're capable of handling everything in one streamlined process, all services under one roof, so you get the benefit of working with us by one time line versus 3 or 4 companies and 3 or 4 time lines.

Flexibility:

We react quickly to your changing needs. Our working time and style is flexible to meet your variable needs. To us, Dedication to the highest level of customer service is our main mission.

You Can Focus On Your Design and Market

You can rely on us to handle all aspects of your printed circuit assembly projects. We are able to handle your pcb layout, circuit board fabrication, pcb assembly , parts sourcing and final assembly , so you can focus on your core competencies like research ,development and marketing.